YQP36预加水盘式成球机设计

摘 要:为了满足现代机立窑水泥生产过程中预加水成球的技术要求,发展第六代预加水盘式成球机,从而保证料球的粒径均匀性、高强度、高孔隙率和高产量,提高水泥的煅烧质量和产量,本课题设计了YQP36预加水盘式成球机。根据最新的技术要求对 YQP36预加水盘式成球机的结构、传动系统和刮刀系统进行了改进设计。本次设计采用理论设计和经验设计相结合的方法,在通过类比设计保证机架与支架的支承强度的基础上优化了传动系统和刮刀系统。参考实践生产中的一些改进经验,首先进行了总体方案的论证;然后根据分析的结果来计算各传动轴的轴向力、扭矩以及功率,并校核了轴和螺栓的强度,从而选择电机和减速机型号及设计其他相关零部件。根据已确定的部件参数分析拟定传动装置的运动简图,分配各级传动比,确定了传动零件的结构;接着对 YQP36预加水盘式成球机的润滑和密封方式加以确定;最后对预加水盘式成球机的维护修理加以说明,从而完成预加水盘式成球机的总体结构设计。此次设计本着高产量、高质量成球,稳定运转的原则,实现了现代预加水盘式成球的节能、经济、环保、可扩展的目的。

关键词: 成球;预加水;刮刀;料球

The Design of YQP36 Disc Prewatering Pelletizer

Abstract: In order to satisfy the technical requirement of prewatering pelletizing in the process of cement production with modern kiln and develop the sixth generation of prewatering pelletizer, the topic which is designed is YQP36 Disc Prewatering Pelletizer. Consequently the proportion of diameters, the high strength, the high holes rate and the high output of raw meal pellets could be assured of. According to the new requirements, the structure, the transmission system and the drawknife system of YQP36 Disc Prewatering Pelletizer are improved and designed. This design has been completed by the method which combines theories design with experience design. The transmission system and drawknife system are optimized basing on that the strengths of chassis and support are assured with analogy design. Firstly, the projects of designation and improvement of prewatering pelletizer are demonstrated, including the structure, the ways of delivering the motivation and drawknife system by referring some improvement experience from production practice; Secondly, based on the analytical results, axial force, the torque and power are computed so that the electromotor, decelerator and other corresponding components could be determined; Thirdly, according to the parameters of the parts which has already been assured, the simple exercise diagram of the transmission device is analyzed and drawn up and the ratios of all levels are assigned. Then the structure design is carried on and the strength of part is followed to be checked. The ways of lubricant and seal of the equipment are determined in succession. Finally, the whole overall arrangement scheme of YQP36 prewatering pelletizing equipment is designed. This design is in the light of the principle of the high yield, high quantity of pelletizing and stable operation. In addition, the requirements of YQP36 will be satisfied, including economy of energy, economy, environmental protection and enlargement.

Key words: pelletizing; prewatering; drawknife; raw meal pellet

目 录

1 前 言………………………………………………………………………………………1

2 总体方案论证……………………………………………………………………………2

2.1 料球的技术要求及对成球盘的技术调整分析………………………………………………2

2.2 盘体的技术分析论证……………………………………………………………………2

2.3传动机构的技术分析论证…………………………………………………………………2

2.4刮刀系统的分析论证………………………………………………………………………2

2.5 刮刀盘、刮刀杆和刀头分析论……………………………………………………………3

3 盘式预加水成球机综合参数计算………………………………………………………4

3.1生产能力计算……………………………………………………………………………4

3.2功率计算…………………………………………………………………………………4

3.3 成球机盘高计算…………………………………………………………………………4

3.4 成球机转速计算…………………………………………………………………………5

3.5圆盘倾角计算……………………………………………………………………………5

3.6料球运动基本方程………………………………………………………………………5

4机械传动装置的总体设计………………………………………………………………8

4.1 选择电机………………………………………………………………………………8

4.2 选择减速机 ………………………………………………………………………………8

4.3计算传动装置的各参数…………………………………………………………………9

5机械传动件设计…………………………………………………………………………11

5.1皮带传动设计……………………………………………………………………………11

5.2齿轮传动设计……………………………………………………………………………13

5.3 Ⅲ轴设计及校核…………………………………………………………………………16

5.4 轴承校核………………………………………………………………………………20

5.5 双键(Ⅲ轴)设计校核(普通平键)…………………………………………………………21

5.6盘体固定螺栓校核………………………………………………………………………21

6传动机构的密封润滑……………………………………………………………………23

6.1密封……………………………………………………………………………………23

6.2润滑……………………………………………………………………………………23

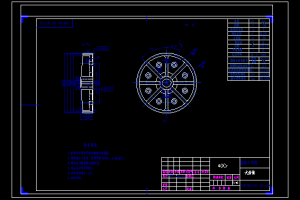

7预加水盘式成球机的总体设计…………………………………………………………24

8预加水盘式成球机使用维护和修理……………………………………………………25

8.1预加水盘式成球机的使用维护……………………………………………………………25

8.2预加水盘式成球机的修理与修理周期……………………………………………………25

9 结 论……………………………………………………………………………………27

参考文献……………………………………………………………………………………28

致 谢………………………………………………………………………………………29

附 录………………………………………………………………………………………30