变速箱开式试验台设计

摘 要

变速器是现代汽车的一个主要装备,其性能直接影响到汽车的动力性、燃油经济性及驾驶性能等. 研究自动变速器与发动机的联合工作特性,需要对自动变速器的性能进行台架试。

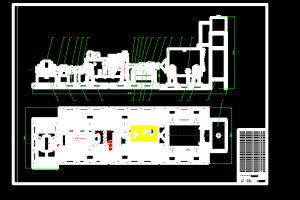

本文从整体上论述了汽车变速箱性能检测系统的测试原理和设计方案, 并从硬件和软件两方面详细阐述了汽车变速箱性能检测系统的组成。介绍了汽车变速器系统综合试验台的主要构成与种类, 着重在机械硬件方面去分析研究开放式及封闭式汽车变速器系统综合试验台的主要结构、特点及工作原理。

本论文研究的目的、意义:我国汽车工业正处于发展和提升时期,变速器在汽车上开始大量装备,这对其设计制造、性能检测与维修提出了迫切要求。目前国产变速器测试设备多为手动、测试精度低、响应速度慢;进口设备,价格较高,集中在少数企业和地区,这种状况无法满足汽车制造及维修行业的需求。为开发具有自主知识产权的、适合我国国情的变速器检测备,提出本研究课题。

关键词:变速器, 试验台, 结构, 分析

DESIGN OF THE OPENING TRANSMISSION TEST-BED

ABSTRACT

The transmission is a main device of modern cars. Its performance directly affects tractate performance, fuel economy and convenient operation of vehicles, etc. Its characteristics must be tested with the test – bed to study the characteristics of the cooperating performance of the engine and the press for its design, test, reptransmission.

This paper discuss the test theory and design project of a test System for the performance of Transmission test-bed,and describe the makeup of the system from hardware and software. This paper introduces the main components and types of the comprehensive testing beds for vehicle transmission system with focus on mechanical hardware, the author analyses their main structures, features, and working principle of the open and closed comprehensive testing beds for vehicle transmission system.

Motive and meaning of the research: In our country automobile industry positive be placed in shape time,Transmission beginning equipped on a lot of motors, this situation Inevitably air. Present domestic Transmission Test-bed mostly turning by hand, test accuracy is low , respond speed is slow; the import equipment price is higher ,concentrate in the minority. This condition can not satisfy the demand of automobile production and maintenance enterprise. In order to develop the Transmission Test-bed which have independence intelligent property right, we propose this research lesson.

KEY WORD:transmission, testing bed, structure, analysis

目 录

第一章 前言.…………………………………….1

- 1.1 研究的目的………………………………..1

- 1.2 研究的依据………………………………..2

- 1.3 试验台的种类………………………………2

- 1.3.1 开式试验台…………………………….2

- 1.3.2 闭式试验台…………………………….2

第二章 试验台总体方案的确定……………………….3

- 2.1 试验台的基本功能…………………………..3

- 2.2 试验台的测试原理…………………………..3

- 2.3 试验台的基本组成…………………………..4

第三章 试验台的基本结构设计……………………….8

- 3.1 联轴器的选择………………………………8

- 3.1.1 变速器输入轴后的联轴器………………….8

- 3.1.2 升速器后的联轴器……………………….9

- 3.1.2 发动机后的联轴器……………………….9

- 3.2 升速器的设计 …………………………….10

- 3.2.1 斜齿圆柱齿轮传动设计…………………..10

- 3.2.2 低速轴的设计…………………………11

- 3.2.2 高速轴的设计………………………….14

- 3.2.4 键的强度校核………………………….16

- 3.2.5 升速器附件设计………………………..19

- 3.3 升速齿轮箱的简单设计………………………19

- 3.4 扭矩转速传感器的选择………………………22

- 3.5 传动结构的设计……………………………22

第四章 试验台性能匹配.…………………………..23

- 4.1 测功机用途及使用范围………………………23

- 4.2 测功机结构及原理………………………….24

- 4.3 测功机工作特性……………………………24

- 4.4 试验台的匹配原则………………………….26