摘 要

钢管水压试验机是通过压力试验产品的特性指标的机器,主要通过压力的测定和耐压时间的测定对各种管件的耐压性能进行测试。在我国的钢管企业中被广泛用于测试产品的质量。

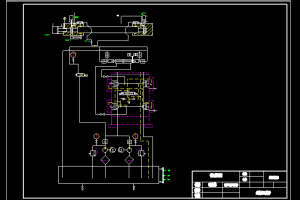

水压试验机试产品的流程如下:

通过送料装置将钢管送至水压试验机的预定密封处→向冲水头和排气头两侧进行径向加压预密封→向钢管充水排气→开始增压→保压一段时间后卸压→两侧进行径向预密封卸压→充水头和排气头退回→钢管退出。其中预密封加压过程的完成的及时程度决定了试验能否成功。

传统的水压实验设备在工作初始阶段由于泄漏会引起水压不稳定的问题,并且由于使用了传统的油液压装置,会对环境造成污染。本文通过对预密封系统进行了重新设计,采用新技术改进原有的试验机密封原理,并使用水液压代替油液压,使钢管水压试验机在对钢管进行水压试验时更加安全、高效从而提高该设备的可靠性。

关键词:水压试验机 预密封 水液压

Abstract:Steel pipe hydro-static testing machine is a machine by the characteristic parameters of pressure testing products. The compression properties of various kinds of pipe fittings performance test through the test of pressure and pressure time. It is widely used to test the quality of the products in our country.

The testing process of the hydro-static testing machine is as follows:Sending steel pipe to reserve seal of hydraulic press→Radial sealing pressure→ Water filling exhaust → Booster →Holding the pressure → Pressure relief → Radial sealing pressure relief → Exit the water headers and exhaust headers → Exit the tube.The seal compression process is the key part witch determines the test success.

Traditional hydraulic equipment reliability test equipment have some flaws.In the initial stage of the work of water leakage will cause the instability problem, and the use of a conventional hydraulic system, causing pollution on the environment.This paper redesign the sealing system by using high-technology to improve the original principle, and use water instead of oil in hydraulic system. The new system makes steel pipe hydro-static testing machine for steel pipe during hydro-static test is more secure and efficient and the reliability of the device can be improved .

Keywords:hydro-static testing machine Preliminary seal Water hydraulic

目 录