摘 要

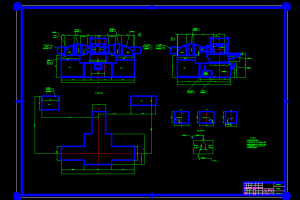

本文主要介绍ZH1105柴油机气缸体三面攻螺纹组合机机床的设计。因为工艺方案在很大程度上决定组合机床的结构配置和实用性能。因此应根据被加工工件的特点,按组合机床常用的设计方法、充分考虑各种影响因素,并分析后拟订出可靠的工艺方案。在设计多轴箱时,根据加工工序图确定所需设计的组合机床上完成的工艺内容,加工部位的尺寸、精度、表面粗糙度及技术要求,加工用的定位基准、压紧部位以及被加工零件的材料、硬度和在本机床加工前的加工余量。认真分析研究并确定设计方案,计算所需的功率,设计出适合加工本工序的组合机床。

关键词:组合机床; 加工工序; 多轴箱; 传动系统

Abstract:

Main introduction in this text ZH1105 diesel engine air cylinder three offend the design of the thread combination machine machine bed, stud.Because the craft project decides to a large extent the construction that combine the machine bed installs with the practical function.So that should according to the characteristics of the work piece, according to certain principle, knot with combine the in common use design in bed in machine method and consider every kind of influence factor well, combine the economic analysis draw up a dependable craft project behind.Complete in many stalks a combination for, according to processing work preface diagram certain the design needed machine bed that design the craft contents, process the rough a fixed position for and technique requesting, processing using basis in size, accuracy, surface of the part and add to press the part and is processed the material, degree of hardness of the spare.

Key words: Combination machine bed; Process the work preface;

Many stalks box; Spread to move the system

目 录

0前言·····································································································································1

- 总体方案论证·················································································································3

2、计算部分···························································································································4

2.1、多轴箱的设计··············································································································4

2.2、切削转矩的计算·········································································································5

2.3、主轴直径的计算和主轴外伸尺寸的确定·································································6

2.4、切削速度的确定·········································································································6

2.5、切削功率的计算········································································································6

2.6、机床动力参数的计算·································································································7

2.6.1、电动机功率的确定·······························································································7

2.6.2、电动机的选择·······································································································7

2.7、攻螺纹主轴转速的计算·····························································································8

2.8、切削用量的计算·········································································································8

2.9、生产率计算················································································································8

2.9.1、理想生产率计算···································································································9

2.9.2、实际生产率计算··································································································9

2.9.3、机床负荷率计算··································································································9

2.10、多轴箱的传动系统设计··························································································9

2.11、根据原始依据图计算主轴坐标··············································································11

2.12、多轴箱中齿轮模数、齿数的确定··········································································12

2.13、合拢轴的位置及齿轮齿数的确定··········································································14

2.14、传动轴坐标计算·····································································································15

2.15、验算中心距误差·····································································································16

2.16、轴的校核·················································································································20

2.17、齿轮校核·················································································································22

2.18、靠模体的设计··········································································································22

3、设计部分························································································································23

4、结论································································································································24

5、小结································································································································25

致谢······································································································································25

参考文献······························································································································26

附件清单······························································································································27