摘 要

在现代工业中,对超大工件的测量是一个难题。各项数据的测量功能很分散,没有办法用同一个仪器对工件的长度、直径、同轴度、表面粗糙度等数据进行测量。虽然近几年也有三维扫描仪等仪器能够对工件进行全面的测量,但是高昂的价格却没有办法能够使它在工业中广泛的运用。

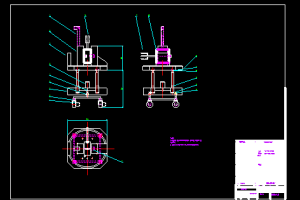

本文对激光测量技术以及机器人技术进行深入的研究,将通过激光测距原理测量长度和直径的机构,用百分表测量同轴度机构,以及用激光测量表面粗糙度的机构结合在一个机器人上,并分析设计机器人的性能、用途、自动化程度、操控方式,以实现设计机器人的多功能测量。并配合辅助机器人,对功能进行实现。而且采用了基于蜗轮蜗杆原理的电动升降杆和电动旋转台,以及全方位轮式移动等装置,使机器人能够实现全方位的移动。

关键词:超大工件;激光测量;机器人

The Design of The Large Workpiece Measurement Device

Abstract

In modern industry, measurement of large workpiece is a problem. The measurement data is dispersed, there is no way to measure the length, diameter, coaxiality, surface roughness data of workpiece with the same instrument. Although in recent years there are 3D scanners and other equipment to conduct a comprehensive measurement of the workpiece, but the high price but there is no way to make it widely used in the industry.

This paper of laser measurement technology and robot technology for in-depth study, through mechanism of laser ranging principle to measure the length and diameter with dial indicator measuring coaxiality institutions, and with laser measurement of surface roughness of institutions combined in a robot and analysis design robot properties, application, the degree of automation and ways of control, to realize multifunctional measurement robot design. And assist robot to realize the function.. And the use of worm gear principle of electric lifting rod and the electric rotating table based on, and omni-directional wheeled mobile device. To enable the robot to achieve a full range of mobile.

Key words: very large workpiece; laser measurement; robot

目 录