摘 要

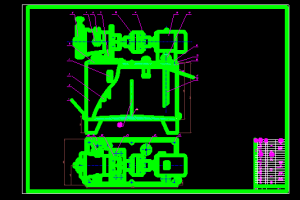

Y41系列单柱校正压装液压机,是一种多功能的中小型液压机床,适用于轴类零件,型材的校正和轴套类零件的压装。它采用手脚联动操作,通过电动机带动液压泵向主油路供油,通过溢流阀,手动换向阀等控制阀对液压系统进行调压换向,以达到各种工作状态。

该液压机结构紧凑,动作灵敏可靠,速度快,能耗小,噪音低,压力和行程可在规定的范围内任意调节,操作简单。在本设计中,通过查阅大量文献资料,设计了液压缸的尺寸,拟订了液压原理图。按压力和流量的大小选择了液压泵,电动机,控制阀,过滤器等液压元件和辅助元件。

关键词:液压机 液压系统 调速回路;

Abstract

Y41 hydraulic machine is one kind of multi-purpose middle scale hydraulic pressure engine, and it could be used in the axis class components, the molding adjustment and the axle sleeve components pressure attire. It uses the hands and feet linkage operation, through electric motor impetus hydraulic pump to main feed circuit , use the overflow valve, control valves and manual cross valve according to each kind of active status.

This hydraulic system framework is compact, movement keen reliable, the speed is quick, the energy consumption is small, the noise is low, the pressure and the traveling schedule may adjust willfully in the stipulation scope, the operation is simple. In this design, through the consult massive literature material, has designed the hydraulic cylinder size, has drafted the hydraulic pressure schematic diagram. According to the pressure and the current capacity size choose the hydraulic pump, the electric motor, the control valve, hydraulic pressure parts, the auxiliary part and filter.

Key word: pressure machine Hydraulic system

Velocity circuit

目 录

摘要··········································································Ⅰ

Abstract·····································································Ⅱ

第1章 绪论·································································1

1.1 课题背景·····························································1

1.2 发展趋势·····························································1

第2章 方案论证···························································3

2.1 传动方案的论证·····················································3

2.2 控制元件的分析·····················································4

第3章 液压机的设计及参数选择·········································5

第4章 工况分析···························································6

4.1 动力(负载)分析及负载循环图··································6

4.1.1 摩擦负载······················································6

4.1.2 惯性负载······················································6

4.1.3 工作负载······················································7

4.1.4 负载循环图···················································8

4.2 运动分析及运动循环图·············································8

4.2.1 位移循环图L—t·············································8

4.2.2 速度循环图···················································9

第5章 确定液压系统主要参数··········································10

5.1 确定液压缸几何尺寸··············································10

5.2 计算液压缸所需流量··············································13

5.3 计算系统所需的压力··············································13

5.4 绘制冲压机主缸工况图···········································15

5.5 液压缸主要零件的结构材料及技术要求·························17

5.5.1 液压缸的基本参数··········································17

5.5.2 液压缸的类型和安装方式··································18

5.5.3 液压缸的主要零件及技术要求·····························18

5.6 液压缸结构参数的计算···········································19

5.6.1 计算液压缸的厚度··········································19

5.6.2 液压缸油口的计算··········································21

5.6.3 缸底厚度的计算·············································21

5.7 液压缸的校合······················································22

5.7.1 液压缸中背压力的校合·····································22

5.7.2 活塞杆的校合···············································23

第6章 拟订液压原理图··················································24

第7章 液压元件和液压油的选择········································26

7.1 液压泵的选择······················································26

7.1.1 确定泵的最大工作压力·····································26

7.1.2 确定液压泵的流量Q和排量q···························27

7.1.3 选择液压泵的规格··········································28

7.1.4 确定驱动液压缸的功率·····································28

7.2 电动机的选择······················································29

7.3 控制阀的选择······················································29

7.4 管道(导管)的选择·················································31

7.4.1 管道内径的确定·············································31

7.4.2 管道壁厚b的计算···········································32

7.5 确定油箱的容量···················································33

7.5.1 液压油的选择···············································34

7.5.2 过滤器的选择···············································34

7.6 联轴器的设计·····················································34

第8章 液压系统的性能验算·············································36

8.1 管路系统压力损失·················································36

8.1.1 沿程压力损失的计算·······································37

8.1.2 管路内的局部压力损失·····································38

8.1.3 阀类元件的局部压力损失··································38

8.2 液压冲击的计算···················································39

8.3 液压系统热分析及其计算·········································41

8.3.1 液压泵功率损失产生的热流量(热量)·····················41

8.3.2 液压系统的散热计算·······································42

第9章 限程装置的设计··················································44

第10章 机架的设计······················································45

10.1 机架材料的选择··················································46

10.2 肋的作用··························································46

第11章 液压系统的安装与调试·········································47

11.1 液压系统的安装··················································47

11.1.1 安装前的准备工作·········································47

11.1.2 管子加工···················································47

11.2 液压系统的调试··················································48

11.2.1 调试前的检查··············································48

11.2.2 启动液压泵·················································48

11.2.3 系统排气···················································49

11.2.4 系统耐压实验··············································49

12.2.5 负载试车···················································49

结论··········································································50

致谢··········································································51

参考文献·····································································52